How to choose materials for springs?

As spring designers, before creating your spring, we need to know precisely what it will be used for, and we need to be aware of factors that may impact how the springs will perform, such as temperature and corrosion.

For instance, if the spring will be used under high temperatures, then we’ll choose – Inconel alloys which are great for extreme environments since it still retains their strength even when temperatures exceed 800 degrees.

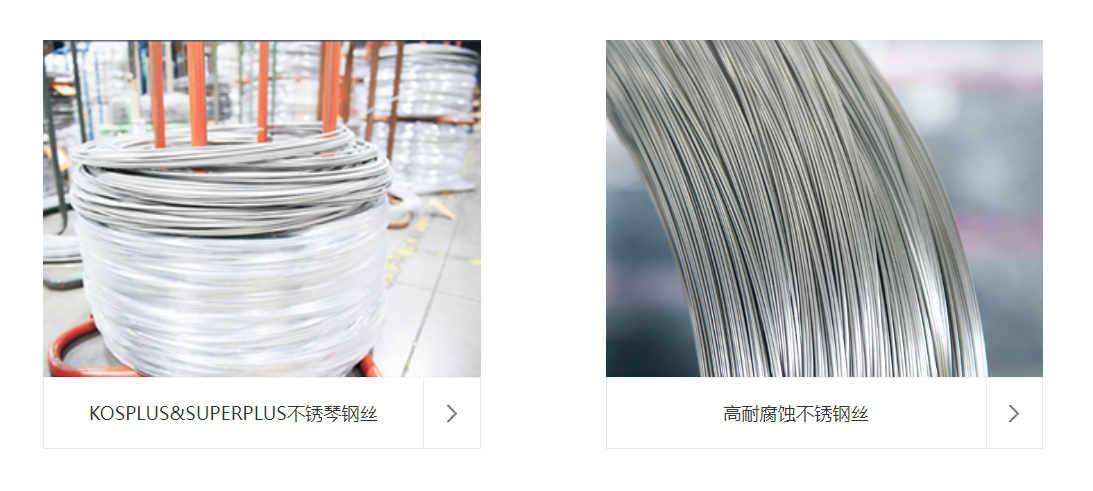

If you work in the oil and gas industry and require springs that can withstand corrosion from saltwater, then stainless steel can be a fantastic choice, as this material for springs won’t rust or weaken even in environments brimming with moisture.

The lifespan of the spring will also play a key role. Springs that are expected to be used thousands or millions of times over their life cycle need to be able to withstand normal wear and tear. For instance, if spring is part of an engine in a car, then it will be in use fairly often, which means materials for springs need to be hard-wearing and durable.

Having the right spring material, therefore, is crucial to the manufacture of a product that will meet the demanding requirements of your project and of the industry, and that will stand the test of time.

If you want to know more about our company, you can take a view of the following videos.

>>>>>Who we are?

>>>>>Our production line?

>>>>>Our package.

>>>>>Our Inspection.

>>>>>Our people:

What springs you are searching for?

Compression sprins>>>Detaills

Extension sprins>>>Details

Disc sprins>>>Details

Die sprins>>>Details

Lock washers>>>Details