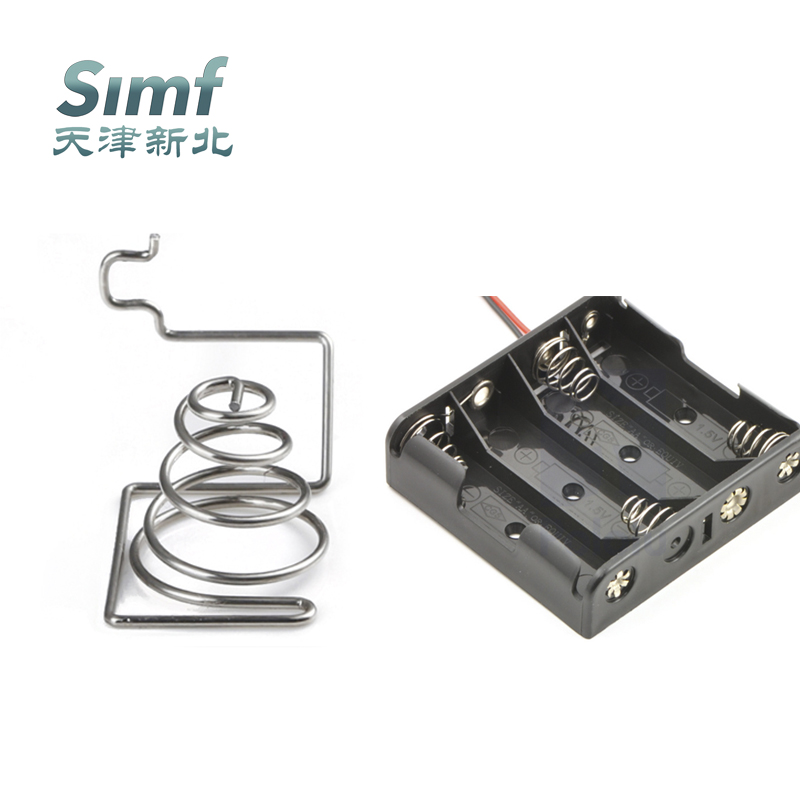

Battery springs

Also known as battery contact springs or battery terminal springs, are components used in various electronic devices to establish electrical connections with batteries. These springs are designed to provide consistent pressure and maintain a secure connection between the battery and the device’s electrical contacts, ensuring proper power transmission.

Key features of battery springs include:

Shape and Design:

They are typically coiled springs made from conductive materials like stainless steel or phosphor bronze. They are engineered in a way that allows them to compress and rebound, applying constant pressure on the battery terminals for a secure connection.

Compression and Resilience:

The springs are designed to compress when the battery is inserted into the device, creating a snug fit between the battery’s terminals and the device’s contact points. When the battery is removed, the spring expands back to its original shape.

Contact Points:

Battery springs have contact points at both ends—one end is attached to the device’s circuit, and the other end makes contact with the battery’s terminals.

Battery Types:

They can be found in devices that use a wide range of battery types, including cylindrical batteries (like AA, AAA, etc.) and coin cell batteries (like CR2032). The springs’ design may vary based on the specific type of battery they are meant to accommodate.

Applications:

Battery springs are used in a variety of electronic devices, such as remote controls, toys, flashlights, portable electronics, medical devices, and more. Any device that requires a replaceable battery is likely to incorporate battery springs.

Durability and Conductivity:

Battery springs need to be made from materials that offer good electrical conductivity to ensure efficient power transfer. At the same time, they should be durable enough to withstand repeated compressions and expansions without losing their springiness.

Customization:

Manufacturers may customize the design and specifications of battery springs to suit the specific requirements of their devices. This includes variations in size, shape, tension, and contact geometry.

Overall, battery springs play a crucial role in ensuring reliable electrical connections between batteries and electronic devices. Their design and functionality contribute to the efficient operation of devices that rely on battery power.

More types of springs we can supply:

Compression springs, Extension springs, Disc springs, Die springs, etc.

Who we are?

Our package.

Our Inspection.

Our people: