How does it install a lock washer?

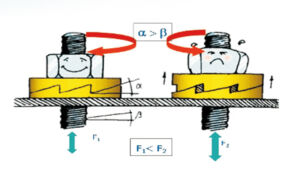

To install the Washer, place the preassembled air between the nut and/bolt and the joint material. As the nut or bolt is tightened, one half of the Washer pair will be seated to the joint material and the other half will be seated to the nut or bolt. Tighten joints with the Washers using standard tools. Retightening is not needed. The use of ubricants is highly recommended when installing the Washers. A high quality lubricant designed to prevent seizing will reduce friction during installation and improve the consistency of clamp load in joints.

When installing the Washers in a common application, expect an increase in required torque over recommended installation torque to achieve proper clamp load and maximum joint safety.

Removal and reuse

Removing the Washers requires no special tools or procedure. Simply loosen the joint in the normal method and check the Washer to ensure cam faces disengage. While the Washers are typically reusable, it should always be inspected for deformation or excessive wear before reuse. If the Washers appear deformed or heavily worn,

discard and use a new pair.