A fatigue test on disc springs involves subjecting these mechanical components to repeated cycles of loading and unloading to assess their endurance and performance under cyclic loading conditions.

Here’s how a fatigue test on disc springs typically works:

Test Setup:

Specimen Preparation: Disc springs of the desired material and dimensions are selected for testing.

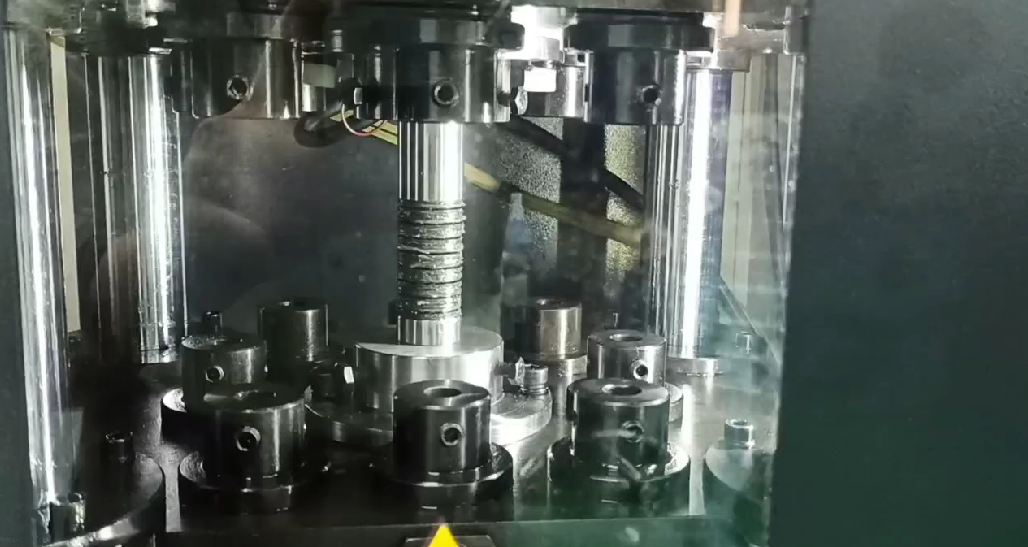

Test Apparatus: Tianjin Simflex has its own testing machine is used to perform the fatigue test. The machine applies cyclic loads to the disc spring while monitoring the number of cycles and the applied load.

Test Procedure:

1. Initial Condition: The disc spring is placed in the testing machine, and an initial load is applied. This load can be a static load or a pre-loading step to mimic real-world conditions.

2. Cyclic Loading: The testing machine then applies cycles of loading and unloading to the disc spring. The loading cycle involves increasing the load on the spring, causing it to compress or deflect. The unloading cycle involves reducing or removing the load, allowing the spring to return to its original shape.

3. Cycle Count: The test continues for a specified number of cycles, which can range from a few thousand to millions, depending on the intended application and the desired level of fatigue life assessment.

4. Monitoring: During the test, various parameters are monitored, including applied load, deflection or compression of the spring, and the number of cycles completed. These measurements help in assessing the spring’s behavior and performance over time.

Data Collection:

1. Stress-Strain Data: By measuring the applied load and the corresponding deflection or compression of the disc spring, stress-strain data can be obtained. This data provides insights into the spring’s material behavior under cyclic loading.

2. Fatigue Life: The main goal of the fatigue test is to determine the disc spring’s fatigue life, which is the number of cycles it can withstand before failure or a significant decrease in performance. The point at which the spring fails or shows signs of failure, such as cracks or permanent deformation, is noted.

Analysis and Interpretation:

The collected data is then analyzed to assess the disc spring’s fatigue behavior. Engineers and researchers study factors such as stress amplitude, stress range, and the number of cycles to failure to determine the spring’s endurance and expected service life under cyclic loading conditions.

Fatigue testing provides valuable information for design optimization and product development, ensuring that disc springs can perform reliably in applications that involve repetitive loading and unloading, such as machinery, automotive suspensions, and aerospace components.